Effortless Custom Ethernet Cable Creation Guide | DIY Network Solutions

Table of Contents

How to Create Custom Ethernet Cables

In today’s digital world, Ethernet cables are essential for connecting devices to the internet and local networks. While you can easily purchase pre-made Ethernet cables, there are situations where creating custom cables is necessary. Whether you need a specific length, want to optimize for performance, or simply enjoy a DIY project, this guide will show you how to create custom Ethernet cables step by step.

Introduction: Understanding Ethernet Cables

Before we dive into the process of making custom Ethernet cables, it’s important to have a basic understanding of what Ethernet cables are and how they work. Ethernet cables are the backbone of wired internet and local area networks (LANs). They transmit data using twisted pairs of copper wires and come in various categories, including Cat 5e, Cat 6, and Cat 6a, each with its own specifications.

Choosing the Right Cable Category

The first step in creating a custom Ethernet cable is selecting the appropriate cable category for your needs. The category you choose will determine the cable’s maximum data transfer rate and its capability to reduce interference. Here are some common Ethernet cable categories:

Cat 5e :

- Suitable for basic home networks.

- Supports speeds up to 1 Gbps.

- Adequate for internet browsing, streaming, and online gaming.

Cat 6 :

- Offers better performance and less interference.

- Supports speeds up to 10 Gbps over shorter distances.

- Ideal for demanding tasks like 4K video streaming and large file transfers.

Cat 6a :

- Designed for professional use and high-performance networks.

- Supports speeds up to 10 Gbps over longer distances.

- Suitable for data centers and enterprise environments.

Choose the cable category that aligns with your specific requirements.

Gathering the Necessary Tools and Materials

To create custom Ethernet cables, you will need the following tools and materials:

Make sure to have all these items on hand before proceeding.

Exploring Different Types of Ethernet Wiring

When creating custom Ethernet cables, it’s essential to consider the type of wiring used within the cable. The choice of wiring can significantly impact the cable’s performance, durability, and suitability for specific applications. Here are some common types of Ethernet wiring:

Stranded vs. Solid Core Wiring

- Consists of multiple thin strands of copper wire twisted together.

- Offers flexibility and is less prone to breakage due to bending.

- Ideal for patch cables and situations where frequent movement is involved.

- Suitable for short cable runs.

- Comprises a single, solid strand of copper wire.

- Provides better electrical performance and is less affected by interference.

- Suited for in-wall installations and longer cable runs.

- Less flexible than stranded wiring, making it less suitable for applications with constant movement.

Shielded vs. Unshielded Twisted Pair (UTP) Wiring

- Features additional shielding, typically made of foil or braided metal, around the twisted pairs.

- Provides better protection against electromagnetic interference (EMI) and radio-frequency interference (RFI).

- Suitable for environments with high levels of interference, such as industrial settings.

- Offers improved signal integrity and is commonly used in high-performance networks.

Unshielded Twisted Pair (UTP) Wiring :

- Lacks additional shielding around the twisted pairs.

- Commonly used for standard Ethernet applications in homes and offices.

- More affordable and easier to work with than shielded wiring.

- Effective for short to medium cable runs in interference-free environments.

Plenum vs. Non-Plenum Wiring

- Designed for use in plenum spaces, which are the air-handling spaces in buildings.

- Made from materials that meet specific fire and safety standards.

- Ideal for installations where building codes require plenum-rated cables.

- Slightly more expensive than non-plenum options.

Non-Plenum Wiring:

- Suitable for general indoor installations where plenum-rated cables are not required.

- More cost-effective and readily available than plenum-rated alternatives.

- Should not be used in plenum spaces due to fire safety concerns.

Outdoor and Direct Burial Wiring

- Designed for outdoor use and exposure to the elements.

- Features a weather-resistant jacket and UV protection.

- Suitable for connecting outdoor devices like security cameras or access points.

- Specifically engineered for burying underground without the need for conduit.

- Resistant to moisture and soil conditions.

- Ideal for outdoor installations where cables need to be buried for long distances.

When creating custom Ethernet cables, it’s essential to choose the right type of wiring that aligns with your specific application and environmental conditions. Consider factors like flexibility, interference, safety requirements, and installation location to make an informed decision.

Understanding Ethernet Wiring Standards: T568A vs. T568B

When creating custom Ethernet cables, it’s crucial to follow the correct wiring standard to ensure compatibility with your network. There are two primary wiring standards: T568A and T568B.

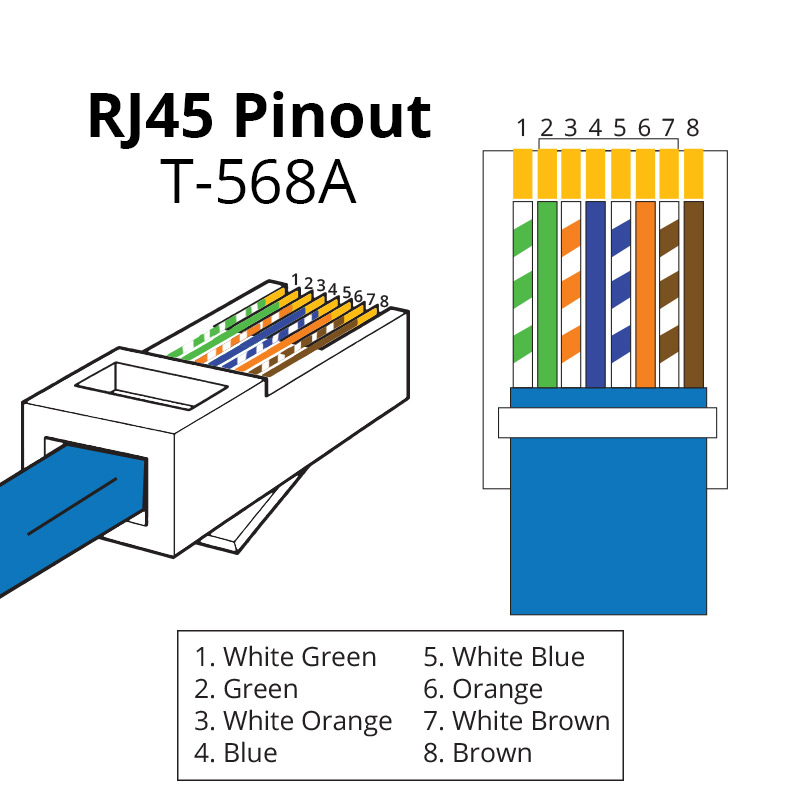

T568A Wiring Standard

T568A Wiring Standard - showmecables.com

The T568A wiring standard is one of the two most commonly used standards for Ethernet cable wiring. In this standard, the wire order for the RJ45 connector is as follows:

- White/Green

- Green

- White/Orange

- Blue

- White/Blue

- Orange

- White/Brown

- Brown

T568A is often used for residential and some commercial networks.

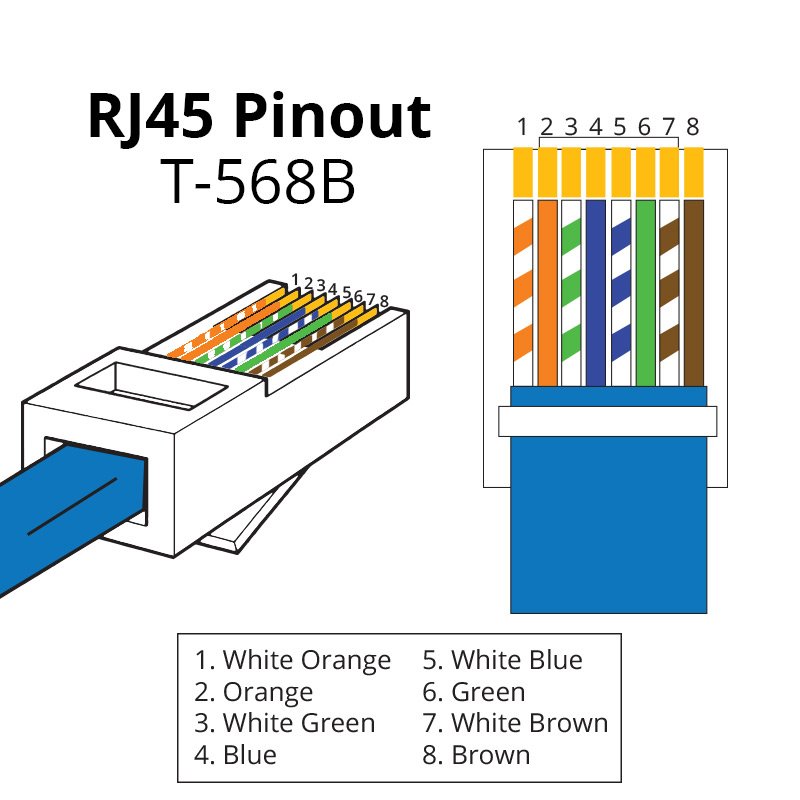

T568B Wiring Standard

T568B Wiring Standard - showmecables.com

The T568B wiring standard is the other widely adopted wiring standard. It has a slightly different wire order for the RJ45 connector:

- White/Orange

- Orange

- White/Green

- Blue

- White/Blue

- Green

- White/Brown

- Brown

T568B is more commonly used in commercial and industrial settings.

Both T568A and T568B standards are acceptable for Ethernet cables, but it’s essential to use the same standard on both ends of a cable to ensure proper connectivity.

Different Types of Ethernet Cables: Crossover vs. Patch

When creating custom Ethernet cables, you may encounter two main types: crossover cables and patch cables. Each serves a different purpose in network setups.

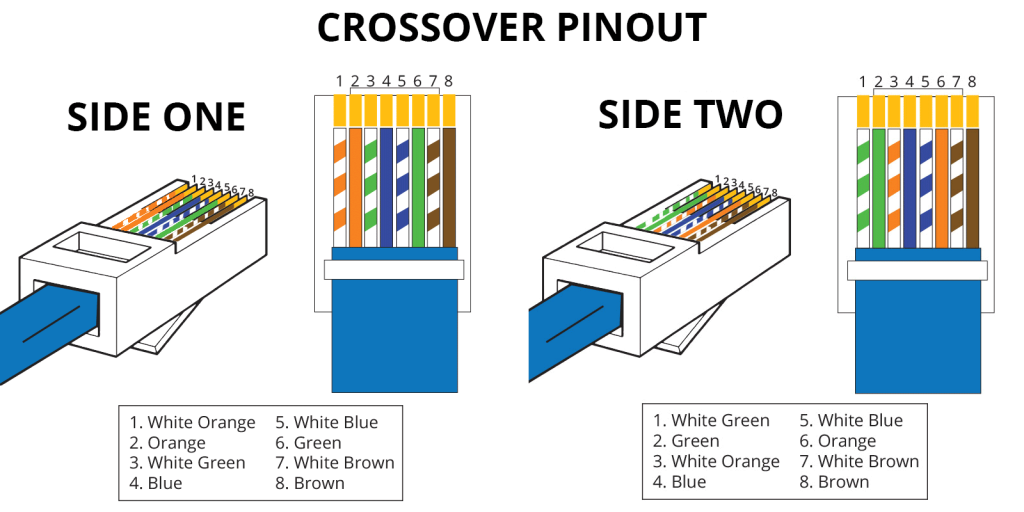

Crossover Cables

Crossover cables are designed to connect two similar devices directly, such as two computers or two switches, without the need for a network hub or switch. These cables use a specific wiring configuration to allow data transmission between devices.

Crossover Ethernet Cable Wiring - showmecables.com

Crossover Cable Wiring:

- Send (TX) on one end connects to Receive (RX) on the other end.

- Receive (RX) on one end connects to Send (TX) on the other end.

Crossover cables are less common today due to the auto-sensing capabilities of modern network devices.

Patch Cables

Patch cables, also known as straight-through cables, are the most common type of Ethernet cables. They are used to connect different types of devices, like computers to switches or routers. Patch cables use the same wiring standard (T568A or T568B) on both ends.

Patch Cable Wiring:

- Both ends use the same wiring standard (e.g., T568A on both ends or T568B on both ends).

Patch cables are versatile and widely used in home and office networks for connecting various devices to the network infrastructure.

When creating custom Ethernet cables, ensure that you select the appropriate type (crossover or patch) based on your specific networking needs.

Step-by-Step Guide to Creating Custom Ethernet Cables

Now that you have the required tools and materials, let’s get into the nitty-gritty of making your own Ethernet cables.

1. Measure and Cut the Cable

- Measure the desired length of your custom cable.

- Use the cable cutter to trim the cable to the appropriate length.

2. Strip the Cable Jacket

- Use the cable stripper to carefully remove about 1.5 inches of the outer jacket, exposing the inner twisted pairs.

3. Untwist and Arrange the Pairs

- Untwist the twisted pairs and arrange them in the required order according to the Ethernet wiring standard you’re following. Common standards include T568A and T568B.

4. Trim and Align the Wires

- Trim any excess wire to ensure all the wires are of equal length.

- Carefully align the wires according to the chosen wiring standard.

5. Insert the Wires into the RJ45 Connector

- Slide the aligned wires into the RJ45 connector, making sure they reach the end of the connector.

6. Crimp the Connector

- Place the connector in the crimping tool and squeeze it firmly to secure the wires in place.

7. Test the Cable

- Use an Ethernet cable tester to check for continuity and ensure there are no wiring errors.

8. Label and Organize

- Label the custom cable for easy identification.

- Organize your cables neatly to avoid tangling and potential damage.

Conclusion

Creating custom Ethernet cables is a practical skill that can come in handy for various networking needs. By following the steps outlined in this guide, you can make Ethernet cables tailored to your specific requirements. Remember to choose the right cable category, gather the necessary tools, and follow the wiring standards for reliable and efficient connections.

Custom Ethernet cables not only offer flexibility but also allow you to optimize your network’s performance. Whether you’re setting up a home network or managing a professional IT infrastructure, knowing how to create custom Ethernet cables is a valuable skill.

Start crafting your custom cables today and enjoy the benefits of a network tailored to your needs!

References

- Ethernet Cable Wiring Standards

- Ethernet Cable Categories

- Ethernet Cable Crimping Guide

- Ethernet Cable Testing

Creating custom Ethernet cables is a rewarding DIY project, and it allows you to have full control over your network setup. Whether you’re a tech enthusiast or need cables for specific applications, this guide will walk you through the process step by step. Don’t hesitate to explore the world of custom Ethernet cables and enhance your networking capabilities.

Lastly, if you’ve made it this far, you might be interested in reading our guide on Setting up a Ubiquiti Unifi Home Network .

Disclosure and Affiliate Statement:

Affiliate Disclosure: We may earn a commission from links on this page. These commissions support our website and the content we provide. Rest assured, we only recommend products/services we believe in. Thank you for your trust! Click Here to Learn More